Downhole Gas Separator

Overview

In all production, naturally occurring gases enter the wellbore and create pumping inefficiencies. If left untreated, these inefficiencies can severely diminish production. These gases can also interfere with rod pump performance, resulting in increased maintenance costs and unnecessary pump failures.

The revolutionary patented SPIRIT Downhole Gas Separator™ puts an end to the efficiency-robbing gas interference in rod pumped oil wells. It is a simple, set-and-forget downhole tool that sits between the packer and rod pump. Using a patented internal baffling system, the tool agitates and breaks apart high GLR emulsions for more effective separation of gas and fluids. The gas exits the tool and is produced up the casing, while pure production fluid is fed from the tool to the pump.

The SPIRIT Downhole Gas Separator virtually eliminates the problem of poor pump efficiency and gas-lock from gassy producing wells. The result for you is more effective gas separation, more reliable pump performance and increased productivity.

Key Features

- Increased Productivity. By more effectively separating gas and liquids, you experience more reliable pump performance and decreased downtime.

- Minimal Intervention. The tool is completely self contained and has no moving mechanical parts, providing reliable, low-maintenance performance.

- Quality Construction. The SPIRIT Downhole Separator tool is manufactured from durable, corrosion-resistant materials to be successful in even the harshest environments.

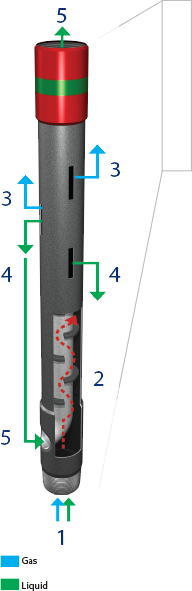

How it Works

- Fluids and gas enter at the bottom of the separator and travel up between the outer and inner tubing.

- Baffles on the inner tubing create turbulence that aids in breaking apart emulsions. Then liquid and gas move upward and out the top portals

- The separated gas flows freely up the casing to the surface

- Fluids drops down inside of the casing creating an artificial sump

- Gas-free fluid then enters the pump intake tube and travels up the inner tube

Sands and Solids

Try the patented SPIRIT Sand and Solids Separator in your field and compare the frequency of maintenance and the cost savings. You’ll experience the highest productivity and the lowest maintenance need of any of your producing fields.

- Reduces destructive failures caused by sand, salt, scale, corrosion, asphalthenes, and other solid contaminants

- Optimizes downhole pumping for efficiency and longer component life

- Placed below the rod pump

Product Applications

- Production flows with higher GORs

- Horizontal completions

- Above the perforation completion

Available in two sizes

- 2 3?8" x 40'

- 2 7/8" x 40'

Documentation

Related Products

Well Monitoring Equipment used frequently with the Downhole Gas Separator

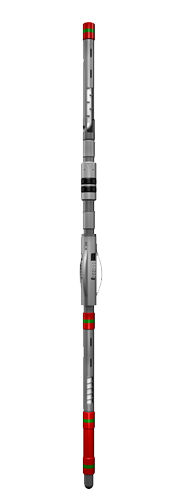

Hybrid-X Downhole Gas/Sand/Solids Separator

Prevent gas, sands and solids from reducing oil production.

Spirit® Genesis™ Intelligent Asset Manager

Optimizing Management of Your Well Assets.

Intelligent Speed Drive XR-1

Protect and Optimize Pumping Unit Assets.

Downhole Sand & Solids Separator

Reduces sand and solids contamination.