LUFKIN Rod Guides

Lufkin rod guides reduce rod and tubing wear, improve well efficiency, and extend equipment lifespan by ensuring smoother and more consistent rod movement in oil and gas wells.

LUFKIN Rods rod guides are designed and manufactured using the most advanced designs and thermoplas-tics.

Our guides will maximize the life of your most demanding applications including wells that are deviated or directional, high temperature, corrosive, high water cuts and solids.

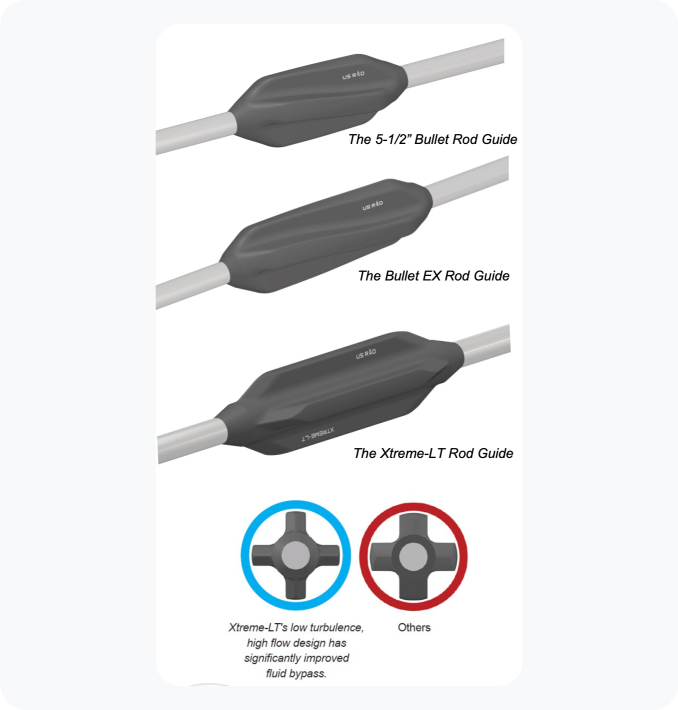

Bullet

The curved vane design distributes the load over a wider portion of the tubing and increases the ability of the rod string to rotate when used with a rod rotator. The 5-1/2” Bullet rod guide offers superior protection with greater EWV (erodible wear volume) than the competition. Every Bullet has wear indicators molded into the guide for a quick visual confirmation of when it’s time for replacement.

Better Design, Better Defense, Better Flow

Every Bullet sucker rod guide has extended tapered ends that minimizes fluid drag and lowers the chance of corrosion occurring on the leading edge during the downstroke.

Bullet EX

The Xtreme-LT is specifically designed to minimize guide induced corrosion failures and reduce fluid drag in low viscosity fluids. The narrow vanes allow for greater fluid bypass and the longer length stabilized the flow before exiting the Xtreme-LT. The Xtreme-LT is recommended for corrosive environment, high production rates and wells with viscous fluid.

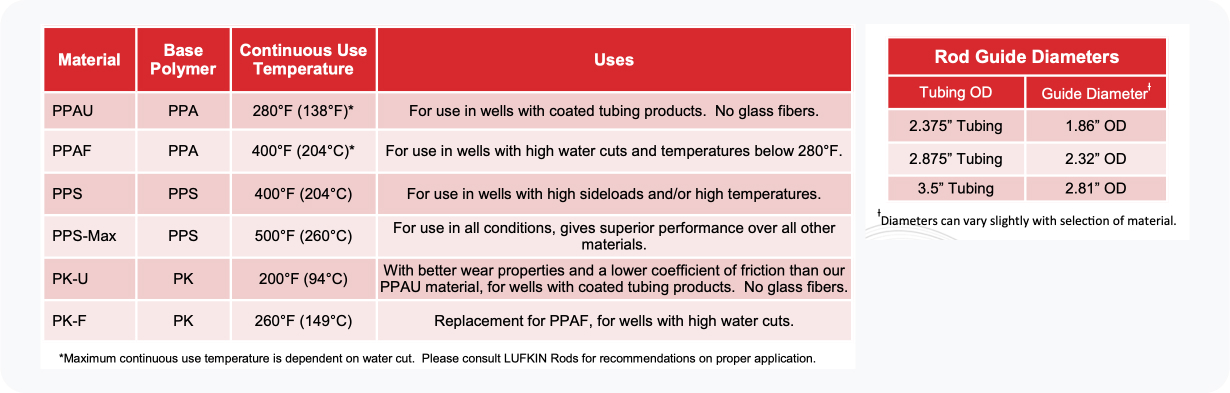

Rod Guides Specifications

PPAU, PK-U

Specifically blended for LUFKIN Rods, materials such as PPAU and PK-U do not contain reinforcing glass fibers. The absence of glass fibers lowers the abrasiveness of the plastic, but also increases the wear rate. These materials are best suited for wells with coated or lined tubing. PK-U has better wear properties than PPAU, but a lower maximum operating temperature.

PK-F

PK-F is the newest plastic introduced to the oilfield. With 20% glass fiber reinforced and added silicon, it gives better wear that PPAF and is non-hygroscopic.

PPS

PPS is another oilfield proven plastic. LUFKIN Rod’s specifically formulated blend has 40% glass fibers. It has excellent wear properties, is non-hygroscopic and has superior chemical resistance. This gives PPS the ability to be used in almost any application below 400°F (204°C).

PPS-Max

Designed for the Eagle Ford, PPS-Max is formulated to give the best performance of any plastic in the oilfield. PPS-Max is selected for use in the most demanding applications. From extreme temperatures to extreme sideloads, PPS-Max combined with the proper guide design will protect your tubing string long after other plastics have failed.

PPAF

PPAF is a proven thermoplastic that has been used in the oilfield since the early 1990’s. Our blend uses 33% glass filled PPA and can be used in most applications. Because PPAF is hygroscopic (absorbs water), the maximum continuous use temperature is limited by the water cut of the well.