Enhanced to meet tomorrow’s intelligent control needs today.

The Wireless Sensors have been designed with state of the art microchips to achieve low noise, high accuracy and resolution with minimum power usage for long life of the rechargeable batteries. Typical range of over 400 ft has been achieved in most installations.

Wireless sensor set up and installation is done efficiently by using the control buttons and LED displays, mounted on the sensor's body, which are used to power up, adjust, and calibrate the sensors when installed at the wellhead without having to view the computer screen.

Wireless sensor set up and installation is done efficiently by using the control buttons and LED displays, mounted on the sensor's body, which are used to power up, adjust, and calibrate the sensors when installed at the wellhead without having to view the computer screen.

Features

- Accurate data = better performance

- Advanced control capabilities

- Flexible programming

- Modular design with multiple communications ports

- Gear reducer torque functions

- Pump tag monitoring

Enhanced Functions

Advanced Control Capabilities At Your Fingertips

More than a rod pump controller, the LWM 2.0 features advanced control functions, including Variable Speed Pump-Off Control, Fluid Pound Avoidance, Torque Functions and Pump Tag Mitigation to optimize production in dynamic conditions. Pump-Off Control can be configured to utilize pump fillage or live or calculated pump intake pressure as a setpoint.

More than a rod pump controller, the LWM 2.0 features advanced control functions, including Variable Speed Pump-Off Control, Fluid Pound Avoidance, Torque Functions and Pump Tag Mitigation to optimize production in dynamic conditions. Pump-Off Control can be configured to utilize pump fillage or live or calculated pump intake pressure as a setpoint.

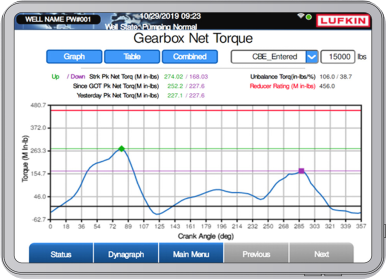

Minimize Risk of Early Equipment Failures, Extend Uptime

Advanced functions such as gear reducer torque and pump tag monitoring provide the operator with the tools to quickly verify that the pumping system is operating within its operating limits, minimizing the risk of early equipment failures. 8 AI, 2 AO, 8 DIO, 2 PDI (Exp.to 8 AI, 4 AO, 16 DIO, 4 PDI Memory 512MB DDR3 RAM, 1GB on Board Flash Temp. Rating Additional Advanced Functions: → Intra-Stroke VSD Fluid Pound Mitigation → Pump Tag Mitigation → Scheduled Pump Card Pattern Matching Analysis

Increased Flexibility, Multiple Communication Modules

The modular design of the LWM 2.0 provides easy field service solutions and includes a communications module complete with multiple Ethernet ports, RS-232, RS-485, and Wi-Fi communications. In a SCADA environment, Modbus RTU and TCP are supported in both master and slave configurations. Connectivity via Ethernet is fully supported. Dynamic Modbus Register Configuration functionality provides the operator with the flexibility to design a most efficient SCADA system.

Control Function

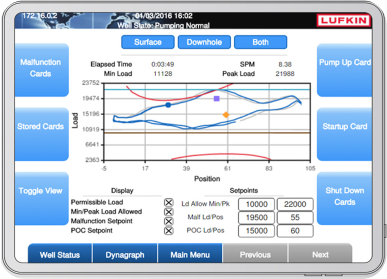

Intuitive dynagraph setup with permissible loads

Gear Reducer Torque

For every stroke, the LWM 2.0 calculates gear reducer torque per 15 deg. Crank Angle intervals utilizing actual Polished Rod Load utilizing the API RP11E method. A VFD is not required to generate the torque plots!