REGEN™ field studies realize power savings of over 10% when using the system, potentially saving thousands of dollars annually.

REGEN™ field studies realize power savings of over 10% when using the system, potentially saving thousands of dollars annually.

REGEN ensures each well is properly optimized and minimizes any power losses by pushing regenerated power back to the grid, resulting in lower power costs and reduced carbon footprint. REGEN technology mitigates power line harmonic distortion to the IEEE 519-2014 standard

REGEN ensures each well is properly optimized and minimizes any power losses by pushing regenerated power back to the grid, resulting in lower power costs and reduced carbon footprint. REGEN technology mitigates power line harmonic distortion to the IEEE 519-2014 standard

Features

- Programmable and automated intra-stroke speed changes on the fly based on live surface or down hole dynagraph data

- Controller and VSD Setup, initialization and control with a single user interface

- Compatible with most available SCADA systems

The Power of Regenerative Technology

REGEN’s advanced engineering combines proven LUFKIN Well Manager™ (LWM) 2.0 technology for well diagnostics, Variable Speed Drive (VSD) capabilities for pump speed regulation, and Active Front End (AFE) technology to regenerate clean power when overhauling loads occur. The all-in-one system eliminates external Dynamic Braking Resistors (DBRs) by returning usable energy to the system. REGEN is exceptionally efficient when multiple loads connect to a single power meter.

The Ideal Choice for Local Power Grids

REGEN is the right choice when the local power grid requires cleaner power, braking resistors pose a hazard, or external harmonic filters do not meet requirements.

One System, One Interface

REGEN’s integrated cabinet and interface makes it very easy to access system information. The user has access to all required information from the front mounted interface, ensuring easy setup and programming.

Quick Start activation can be used to trigger default operating parameters, any of which can be fine-tuned for optimal pump control. If speed or other factors require attention, REGEN can be seamlessly interfaced with remote SCADA systems to allow for access to up to date information and to make on-the-fly adjustments.

Quick Start activation can be used to trigger default operating parameters, any of which can be fine-tuned for optimal pump control. If speed or other factors require attention, REGEN can be seamlessly interfaced with remote SCADA systems to allow for access to up to date information and to make on-the-fly adjustments.

VSD Control Function

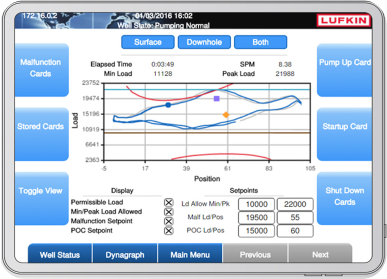

Intuitive dynagraph setup with permissible loads

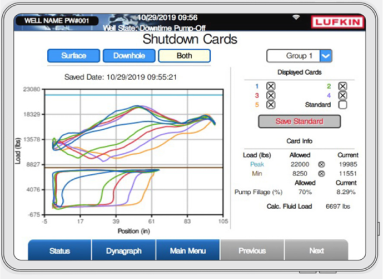

Shutdown cards

Multiple 5-card shutdown buffers, critical for diagnostics and Root Cause Analysis (RCA)

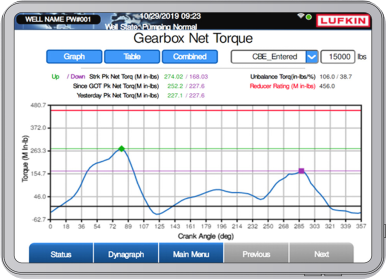

Gear Reducer Torque

For every stroke, the LWM 2.0 calculates gear reducer torque per 15 deg. Crank Angle intervals utilizing actual Polished Rod Load utilizing the API RP11E method. A VFD is not required to generate the torque plots!