Introduction

In order to realize sensitivities that allow us to establish the feasibility of performing any changes in the PCP artificial lift system, it´s necessary to know the current operational conditions and the proportions of the produced fluids (oil - water - gas), being that when there is an incertitude in one of these variables, the effects of the modification in the velocity on the system in the surface as in the bottom equipment are not the most accurate taking the whole system into failures.

In this article we will define a methodology to estimate the Gas-Oil Relationship (GOR) through the production of the gas determined in the annulus between the casing and tubing by using the Software Total Asset Monitor (TAM).

Effects of the Gas Production on the PCP System

A gas production in this artificial lift method, could impact the system in a point of view of a powering requirements in the surface equipment, such as the rods system (torque - axial load), the handle production capacity of the pump in an appropriate speed and the lifetime of the equipment.

We can see below a table that shows us the effects of gas production on two similar wells with the same oil - water production and technical specifications:

|

|

| P.C.P | |

Stage | Potency Electric Motor | Sucker Rod Stress | Speed | Failure Incident |

Multiphase | Low | Low | High | High |

Monophase | High | High | Low | Low |

Also we can see the results of two sensitivities where is considered a monophasic and multiphasic flow

Pump | Rods | Drive Head/ Motor | |||||

Case (Scf/B) | Speed (rpm) | GVF* (%) | Torque (psi-ft) | Axial Load (kips) | Stress (%) | Structure (%) | Consumption (%) |

150 | 113 | 13 | 960 | 37 | 69 | 73 | 83 |

0 | 97 | 0 | 1566 | 45 | 108 | 91 | 134 |

* Gas void fraction: Gas Volume available at suction level.

As we can see on the results submitted, only with one variation of 150 Scf / B, the system goes from critical conditions where it will fail to an optimal stage, thence the importance to establish a high degree of precision on the gas production in order to obtain an appropriate analysis that reflects the current conditions of the well.

Software Required for Evaluation

- Total Asset Monitor (TAM): Used to determine the fluid level and gas production through the annulus space at the well.

- PC-Pump: Software developed by C-FER Technologies for the design and diagnosis of artificial lift systems by progressive cavity pump.

Methodology for the Execution of the Analysis

To perform this type of analysis, it is necessary to verify the following conditions to guaranteeing the precision of the study in the presented order:

- Ensure the system being in stable operating conditions.

- Low casing pressure is required to in order guaranteeing a good pressure restoration for the determination of gas flow on this area.

- Ensure tightness at the head level in order to avoid gas leakages which impede a good pressure restoration.

- Good visualization of the fluid level.

Once the dynamic study is done, the following data will be obtained for the analysis:

- Dynamic level (feet).

- Production of gas by the annular (Mscf/D).

- Bottom hole pressure (psi).

- Pump intake pressure (psi).

With the obtained data and the information of the well loaded into the simulator, the sensitivities will be executed starting off the flowing bottom hole pressure value, assuming an initial GOR value equal to the gas production calculated from the study divided by the flow of oil through of swept at different scales (100 - 150 - 200 scf/Bn).

The effect of increasing the GOR on the simulation would be:

- Decrease the distance to the liquid level, since the volume of gas present in the column tends to expand as a decrease in pressure is generated while ascending from the perforations to the level.

- Increase the intake pressure in the pump, because the gas produced imparts a greater moment to the oil equivalent to the effect appreciated in the artificial lift.

- Increase the production of gas for the annulus since the amount of gas present in the production is increasing.

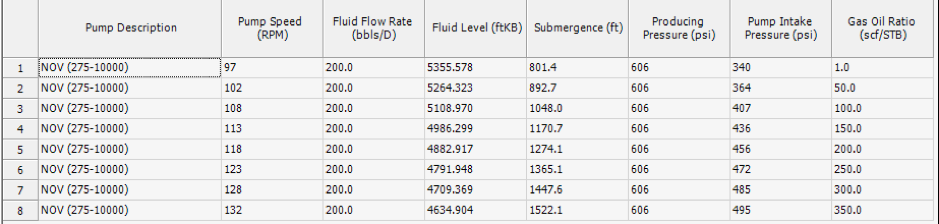

We can see in the table below the sensitivities that show the effect of increasing the GOR value over the variables described before:

The objective of this study will be selecting a GOR value that fits to the conditions of the dynamic study from the point of view of PIP, fluid level and gas production. It is important to highlight that in situations where gas production is very high and crude oil has foamy characteristics, the reliability of the determined pressures can be compromised, so after carrying out the study under stable dynamic conditions for the determination of the Gas production, it is recommended close the flow of gas at the casing level, to depress the fluid column in the annular and so get a better pressures estimation.

Case Studies

Below are results of sensitivities performed, using the methodology described before.

Case A GOR 150 scf/BN

For this case, according to the dynamic study, the production of gas in the annulus area was about 30 Mscf/D, where the production of crude oil was 447 BPD (424 BNPD). The annulus GOR would be 70 scf /B, being this the value used in the initial sensitivity.

Simulation | |||||

Dynamic Study Production Measurements | Initial 70 scf/BN | Final 150 scf/BN | Deviation Final v Real | Deviation Initial v Real | |

Speed (rpm) | 300 | 280 | 300 | 0% | -7% |

Dynamic Level (feet) | 4963 | 5000 | 4827 | -3% | 1% |

PIP (psi) | 424 | 400 | 486 | 15% | -6% |

Pwf (psi) | 683 | 683 | 683 | 0% | 0% |

Gas Production (MscfD) | 22 | 11 | 24 | 9% | -50% |

Gross Production (BPD) | 447 | 435 | 435 | -3% | -3% |

Case B GOR 350 scf / B

For this case, according to the dynamic study, the production of gas in the annulus area was about 20 Mscf/D, where the production of crude oil was 128 BPD (120 BNPD). The annulus GOR would be 180 scf / B, being this the value used in the initial sensitivity.

Simulation | |||||

Dynamic Study Production Measurements | Initial 180 scf/BN | Final 350 scf/BN | Deviation Final v Real | Deviation Initial v Real | |

Speed (rpm) | 150 | 132 | 153 | 2% | -12% |

Dynamic Level (feet) | 6390 | 6697 | 6491 | 2% | 5% |

PIP (psi) | 528 | 482 | 501 | -5% | -9% |

Pwf (psi) | 600 | 544 | 544 | -9% | -9% |

Gas Production (MscfD) | 26 | 13 | 29 | 12% | -50% |

Gross Production (BPD) | Sin Medida | 128 | 128 | N/A | N/A |

Case C GOR 600 scf / B

For this case, according to the dynamic study, the production of gas in the annular area was about 60 MpcnD, where the production of crude oil was 145 BPD (139 BNPD). The annulus GOR would be 400 scf / B, being this the value used in the initial sensitivity.

Simulation | |||||

Dynamic Study Production Measurements | Initial 400 scf/BN | Final 600 scf/BN | Deviation Final v Real | Deviation Initial v Real | |

Speed (rpm) | 200 | 145 | 207 | 4% | -28% |

Dynamic Level (feet) | 5603 | 5931 | 5704 | 2% | 6% |

PIP (psi) | 603 | 655 | 664 | 10% | 9% |

Pwf (psi) | 696 | 696 | 696 | 0% | 0% |

Gas Production (MscfD) | 60 | 37 | 58 | -3% | -38% |

Gross Production (BPD) | 137 | 145 | 145 | 6% | 6% |

As we can see, the results obtained by the sensitivities for the determination of the GOR showed values very close to those recorded in operation and from the point of view of production measures, so it can be considered that the methodology described above can be applied to approximate a GOR that is representative of what is handled by the wells in a real case.

It is also important to mention that as the production of gas increased, there was a greater deviation between the PIP of the study versus the simulation and it is due to the fact that it would be introducing the moment generated by the gas that the TAM does not consider, and is in these scenarios that to determine a better PIP the user should depress the fluid column above the PCP to obtain a better pressure value at the input.

Conclusions:

In scenarios of high uncertainty in relation to gas production, the implementation of the Total Asset Monitor (TAM) is considered feasible for the determination of an GOR that approximates the production of gas from the well, taking as a reference data provided by the software, such as the fluid level, PIP, Pwf and gas production by the annulus; where from the latter a first estimate of the GOR is made.

In short, the purpose of this is to perform different sensitivities by varying the GOR in order to perform a PIP match - fluid level - gas production by the annular.

Using this methodology, several sensitivities with estimated GOR were executed comparing the results with those obtained in operations and production measures where the values shown showed a deviation between -3% and 15%.

It is important to emphasize that is possible to execute this type of analysis if the casing pressure is low enough in order to allow a good gas restoration to determine a production value. It is also necessary to highlight that in foamy crudes due to high turbulence, the determination of a good PIP is affected, so other actions must be taken to establish a better PIP that suits the real conditions.