This note is focus in Monitoring the Progressive Cavity Pumps from two point of view, one as an Optimization Engineer and the other as a File Crew Personal. For each one, tools/methodologies to improve the oil production or equipment protection are explained.

As an Optimization Engineer

An Optimization Engineer could analyze in detail between 06 to 08 wells per day, but normally is responsible for 80 – 120 wells. Thus, is almost impossible to monitoring and evaluate in deep all of them. Therefore, there is available a powerful tool “Automation”; The advantages offered by the immediacy, high frequency and accurate information received by telemetry are indisputable.

In fact, Automation with appropriate parameters and algorithms can perform routine adjustments with minimal supervision, which provides an opportunity to focus on atypical cases, failure analysis, among others.

With the Automation advantage the Oil Production can be maximized by improving uptime through pump protection settings, control devices, and control modes (algorithms). All the settings (High Torque, PIP, CHP, THP, RPM ….) required by the “Pump Controller” and SCADA must be defined by the Productions Engineer and work together with the AIT department to achieve the configuration and integration (Monitoring and Remote Control) between the automation devices and the SDACA.

SCADA Monitoring View

Is a fact that the “Automation” will contribute to your job. But at the same time the optimization engineer would be full of information, alarm, trend curves. In these cases, is really important to discretize the information, and carefully design reports generated by the SCADA that highlight the most important evens.

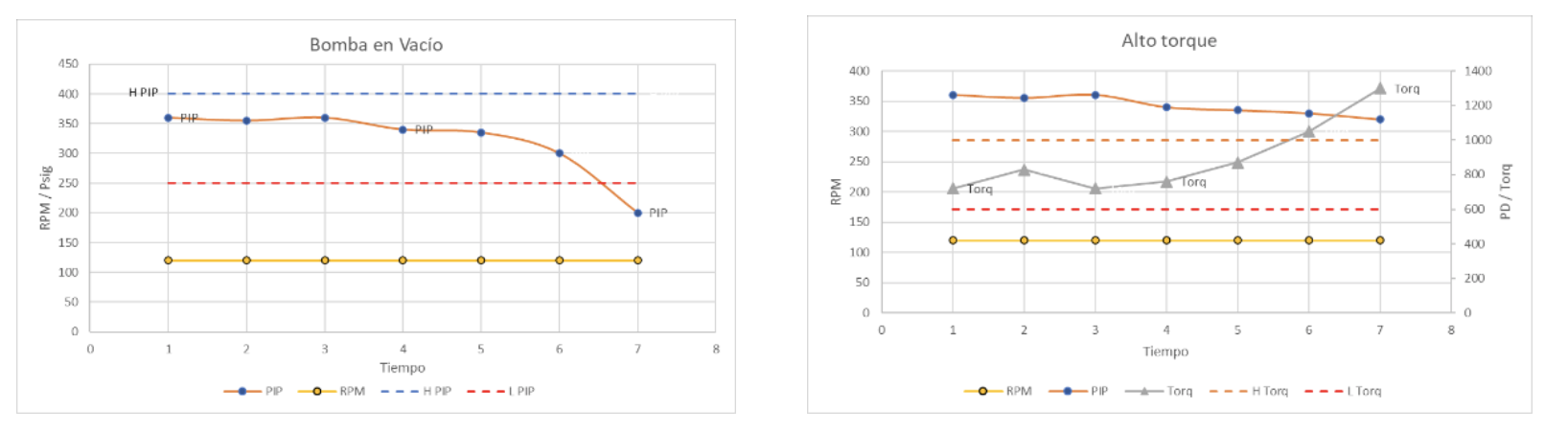

Different Views/Alarm can be configured in your SCADA software; An alarm LOW/HIGH PIP that compare the PIP value whit a previous establish set point. Or compare the PIP with the average of the PIP value in the last 15 days if there wasn’t any major event (Assuming the same pump, no change in RPM, no chemical treatment, among others).

The same things could be done for the TORQUE. Monitoring this parameter allow to detect wear pump, elastomer swell, sands plugs, production of gas, etc. Unlike pressure, the torque is related with mechanical components of the system, and the PIP with the reservoir energy.

Subsurface pump condition estimation

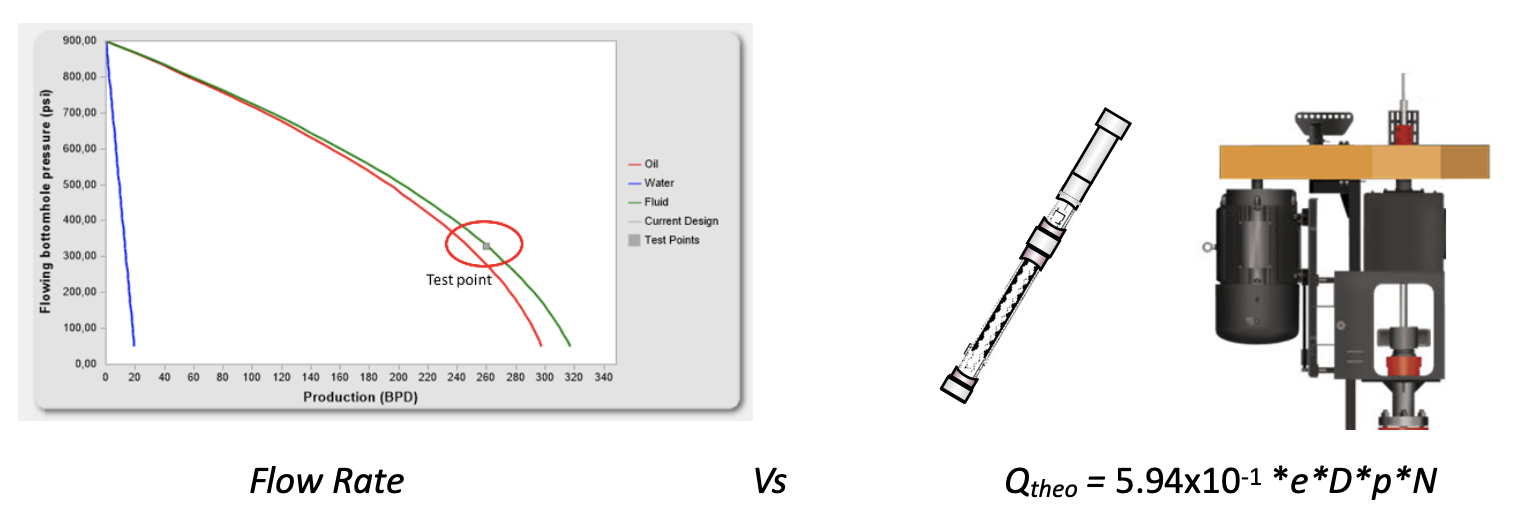

The PIP (sensor / Liquid level) could be used for more than an alarm, this is a referent of the reservoir energy, and the reservoir Inflow (IPR) can be calculate combining PIP, a production test and the static pressure.

The Flow rate calculate with the IPR (PIP, Ps, Ql well test) compared with the pump’s theoretical output capacity can suggest the condition and actual performance of the pumping system.

Flow Rate Vs Qtheo = 5.94x10-1 *e*D*p*N

Monitoring Water Production

The surface facility is design to measure the Well production as much as possible. But, normally there are operations issue or a Production Test is rejected due to some parameters don’t agree with the tendency and could be a long period (two months or more) without the Well Production Information, and during this period many parameters could change a lot, affecting the Well performance. Base on the evaluation of practices apply by different Companies (Operator) our recommendation is to test the well at least twice a month; even better, if an on-line flow meter could be installing would be very useful.

Visual inspection (Water Production).

When you don’t have the enough test facilities at the pump station (too many wells) to evaluate the wells frequently (at least twice a month), would be very useful to determine water cut through surface samples, or even the subjective visual appreciation by the field crew of the amount of water produced. Why? Because, any optimizing proposal or even workover couldn’t be worthy if you are producing a lot of water. Take in considerations that a water outbreak could occur in days if the Artificial Lift System is operated inappropriate and excessive draw down (Reservoir – Bottom hole) is created.

Evaluate this case. Base on the PIP and surface operational parameters is determinate that there is an opportunity to increase production, but due to problems with the Test Separator and the Laboratory, there isn’t water cut information’s. Anyway, a new downhole assembly is installed with a bigger pump capacity, and with the new pump a production increase is expected. But after a couple of weeks, the well is tested and detect that the water cut has change from 20 % to 65 %, so It has been a waste of time and money. And even worse, a further decrease in the PIP/Pwf due to the new pump (Higher volume capacity) will stimulate even more water production.

Chemical treatment (Water Production).

Another indicator that the water proportion had changed is the Chemical Treatment Yield. For example, if emulsion is been pumping through the pipeline, it won’t “break” efficiently and the pipeline pressure will increase. Another consequence of water increase could be observed at the Oil Plant, due to the high water-cuts, the oil cannot be place in specifications (too much water), so the Oil must be “Wash” twice or add heat or more chemical to separate the additional water.

Torque behavior and water increment.

One more indicator of water production increment, is the Torque Behavior (at constant operations conditions). the Hydraulic Torque should increase due to the Hydrostatic Pressure increment (heavier liquid column). This effect will be visible when the Oil Density differs from the Water Density (change in the fluid gradient). This parameter most be analysis carefully because there are two fluid properties affected when a water outbreak occurs, the density and viscosity.

Acoustic Survey / Annular gas flow

The dynamic pumping fluid level, shows the relationship between the pumping rate and the well productivity.

After adjustment the pump velocity is important to take an acoustic survey, this practice provide no just the liquid level and the PIP, also the amount of gas flowing through annular, so if, after an velocity increases the amount of annular gas keep relative constant (Compare with previous acoustic survey/ mini buildup test) this indicate that the gas released at the pump intake keeps relatively constant. But if a strong increase in the annular gas is detected (mini buildup test), indicate that the PIP had dropped to much below the bubble point (saturated fluid), so instead of improve the oil production, it will decrease due to the increase of gas volume entering the pump. Moreover, the reservoir energy (Solution Gas Drive) is been removing inefficiently.

File crew Motoring Activity

Attempts have been made at automating Progressive Cavity Pump (PCP) system installations both from the surface and down-hole, but some are unreliable and/or too expensive. For instance, when the sensors fail, the complete system must be pulled out. Pulling the stator from the well should be the last alternative. Additionally, Automation involve Sensor, Datalogger, Pump Controller (Well manager), VSD Commutations Board, Radios, Antenna, Scada Software. That represent to may failure points that force to have AIT Field Crew.

When there are communications problems, down hole sensors (DHS) are not working or is not economically profitable to have an Automation System, the necessity of a field crew is unquestionable. A specialized file crew that understand in deep the lift system, could carry out Acoustic Survey and has capacity to diagnose Well Conditions.

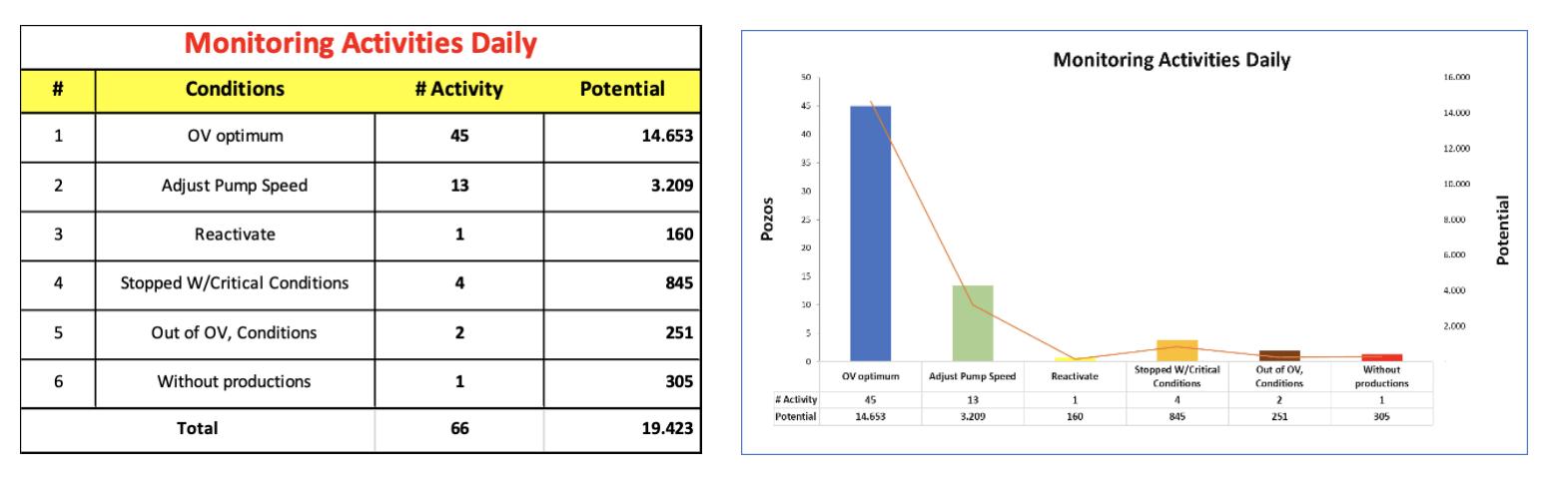

UPC’s Team have been working for the last 09 years Monitoring and Optimizing Wells (+500 Wells, +90.000 Bls/day), based on this experience a field crew, in an average day, could visit 40 to 70 wells (Cluster Arrangements),

carrying out activities to verify optimums condition (Operation Velocity Optimum) or increasing production “Adjust Pump Velocity”, either was an optimization engineer requirement or the field personal detected the incorrect condition and after check all the parameters, reestablish the pump speed. “Reactivate wells”, previous communication with Control Room, the field crew re start the well operation. In an average day a Field Crew could add +3.300 Bls/day to the production.

Additionally, a field crew could prevent damage to the equipment. During the daily activities the field operators can detect: Drive-head oscillations, motors or VSD overheated, damage belts, excessive rod torque, high THP/CHP pressure, leaking stuffing box. In these cases, the well is shut down, the condition is fixed and the well is re-start. Occasionally the irregular condition is not severe, in this case the operation velocity is decrease, but continue operating until everything is coordinate to correct the condition with a minimal downtime.

One of the most relevant situations is when there is not production, the field operators have the capability to diagnostic the well condition, and carryout a sequence to determinate if there is a pump failure, rods disconnected or the well is reestablishing productions. An opportune detection of wells without productions due to subsurface equipment failure, allow the Productions Engineer to designs a new completion and prepare the Workover Job, and minimize the production lost.

Conclusion:

- The Monitoring activity is our daily approach, it could be done successfully applying engineer, taking advantage of the Automation and team work.

- Automation Monitoring in its initial “configuration stage” requires the support of Optimization staff to establish the criteria to control the artificial lift system; And later, the Automation System will optimize Wells Production through pre-established control methods, in other cases will provide alarms that allow us take appropriate action.

- Monitoring activity added value to oil production activity, it is a main activity that can contribute with "barrels" quickly and without investment requirements, as well as, detected issue and correct them quickly or control the situation until corrective maintenance can be done decreasing down time.

Reference:

SPE 52162, S.T. Klein, SPE, InterRep; W.B. Thrasher, SPE, InterRep; L. Mena, SPE, InterRep; E. Quijada, SPE, PDVSA, C. Brunings, SPE, PDVSA; Well Optimization Package for Progressive Cavity Pumping Systems

SPE 63048, P. G. Carvalho, SPE, Petrobras, C. Morooka, SPE, Unicamp, S. Bordalo, SPE, Unicamp, and I. Guilherme, UNESP; CONTROL: PCP – An Intelligent System for Progressing Cavity Pumps.

SPE 53962, L Mena, SPE, and S. Klein, SPE, InterRep; Surface Axial Load Based Progressive Cavity Pump Optimization System.

Robles, J. and A. L. Podio, “Effect of Free Gas and Downhole Gas Separation Efficiency on the Volumetric Efficiency of Sucker Rod Pumps and Progressing Cavity Pumps,” Proceedings of the 43rd Annual Meeting of the SWPSC, 1996.